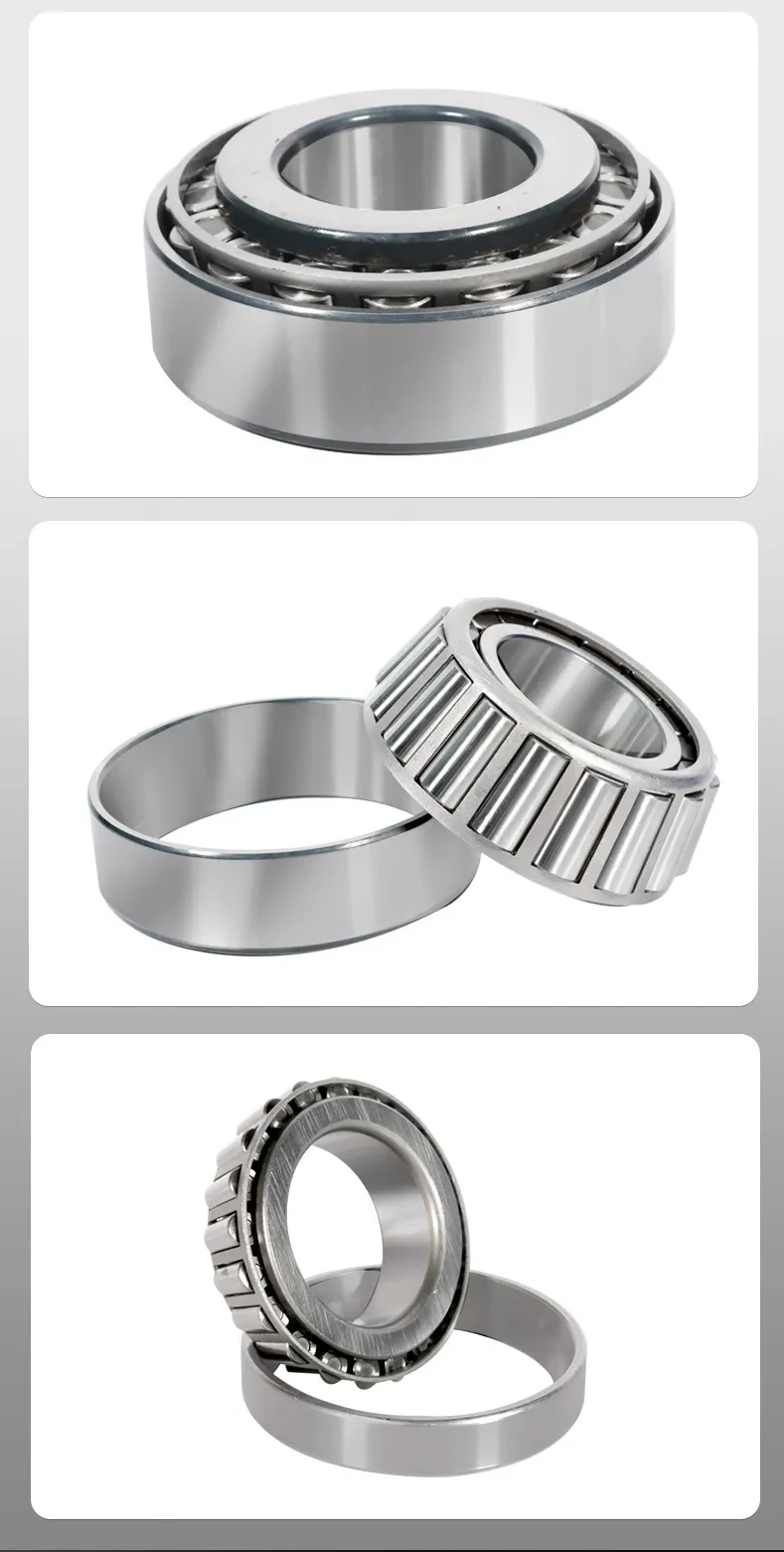

Seven Types Of Tapered Roller Bearings

Product information :

Bearing material: high temperature bearing steel

Name: tapered roller bearing

Product features: high precision, low noise and high speed.

Model: 32220

Packing list:

Bearing *1

Product Description: Seven Types of Tapered Roller Bearings – Reliable, High-Performance Bearings for Diverse Applications

Key Points:

- Seven distinct types of tapered roller bearings to meet various industrial needs

- Excellent load-carrying capacity for radial and axial loads

- High-quality materials for durability and long service life

- Ideal for high-speed, heavy-duty, and high-precision applications

- Precision engineering for smooth and efficient operation

- Wide range of sizes and configurations for different machinery

- Commonly used in automotive, manufacturing, and heavy machinery

- Designed for easy installation and maintenance

- Available in single, double, and multi-row configurations

- Excellent performance in demanding environments such as high temperatures and heavy loads

Overview

Tapered roller bearings are essential components in many industrial and mechanical applications due to their ability to handle both radial and axial loads. The Seven Types of Tapered Roller Bearings are designed to provide reliable performance, high durability, and long-lasting operation across a wide range of industries. These bearings consist of tapered rolling elements that allow for efficient load distribution, making them ideal for applications where both radial and axial forces are present.

Available in various designs and sizes, these bearings offer versatility and precision engineering, ensuring smooth and efficient operation under different environmental conditions. From single-row bearings to more complex multi-row configurations, these bearings are the perfect solution for applications in automotive, manufacturing, and heavy machinery, where high load capacity, speed, and durability are critical.

Seven Types of Tapered Roller Bearings

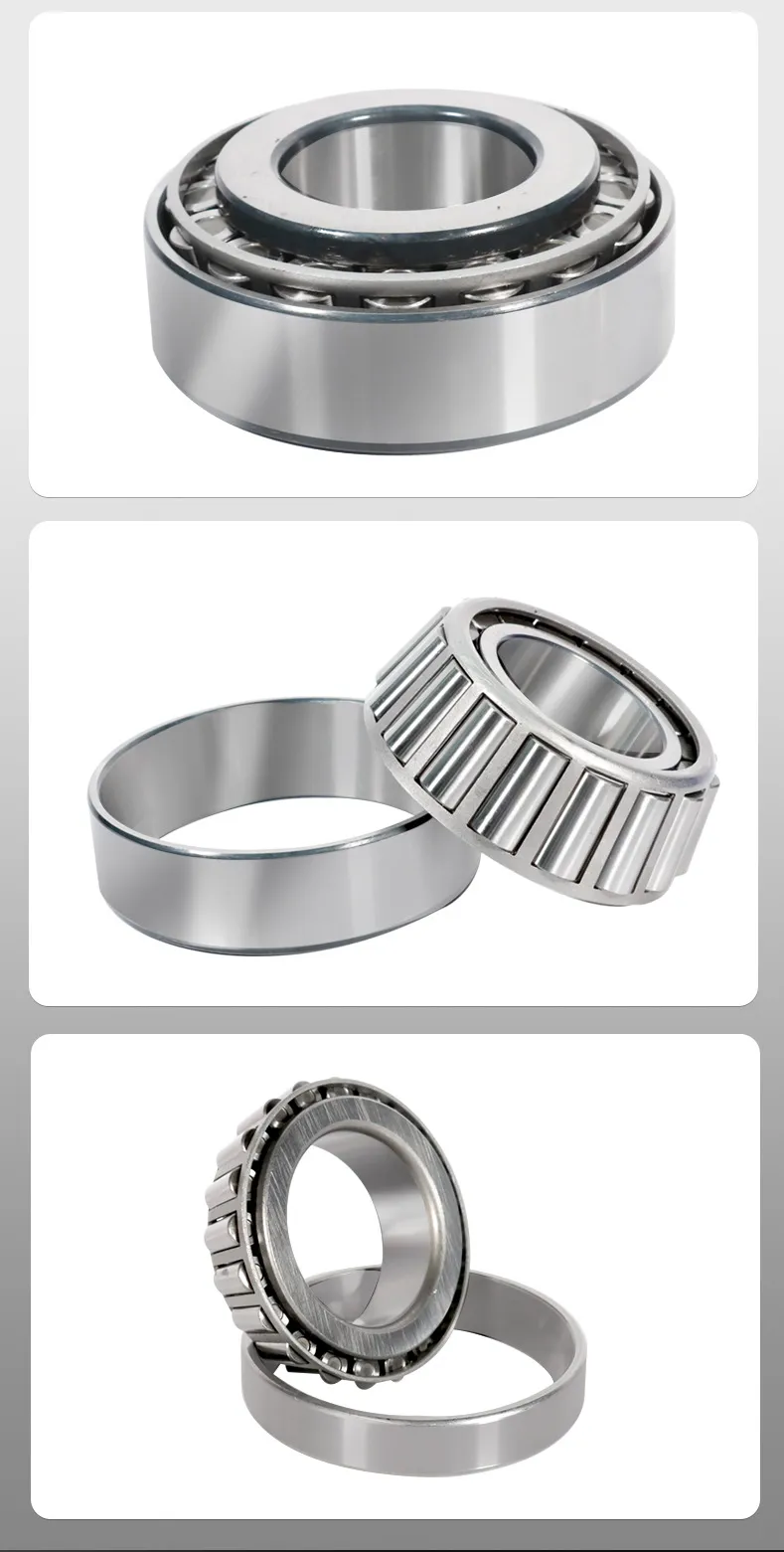

1. Single-Row Tapered Roller Bearings

Single-row tapered roller bearings are the most common and widely used type. They consist of one row of tapered rollers and are capable of handling both radial and axial loads. These bearings are suitable for applications where space is limited, and the load is primarily radial with a small amount of axial load. Commonly used in automotive applications such as wheel hubs and transmissions, single-row bearings are designed for efficient and high-speed performance.

2. Double-Row Tapered Roller Bearings

Double-row tapered roller bearings are designed to handle higher loads than single-row bearings. They feature two rows of tapered rollers arranged symmetrically, which allows them to manage both radial and axial loads more effectively. These bearings are ideal for applications with higher load requirements, such as in the gearboxes of machinery or in heavy-duty applications like mining equipment and construction machinery.

3. Four-Row Tapered Roller Bearings

Four-row tapered roller bearings consist of four rows of tapered rollers, allowing them to provide even greater load capacity and stability. These bearings are specifically designed for heavy-duty industrial applications where both radial and axial forces are extremely high, such as in rolling mills, crushers, and other large machinery. Their robust design ensures reliable performance even in the most demanding environments.

4. Tapered Roller Bearings with a Tapered Inner and Outer Race

This configuration of tapered roller bearings has both the inner and outer races designed with tapered geometry. The design provides optimal alignment of the rollers with the races, resulting in better load distribution and efficiency. These bearings are commonly used in heavy machinery and industrial applications where precision and high performance are required.

5. Double-Row, Full Complement Tapered Roller Bearings

The double-row, full complement tapered roller bearing is designed with two rows of rollers without any cage. This design maximizes the number of rollers and is ideal for applications that require the highest load-carrying capacity. These bearings are typically used in applications with very heavy radial and axial loads, such as large construction equipment, turbines, and power transmission systems.

6. Tapered Roller Bearings with a Sealed or Shielded Design

These bearings feature seals or shields on both sides to protect against contamination and retain lubricant. Sealed or shielded tapered roller bearings are ideal for applications in harsh environments where dust, dirt, or moisture might affect bearing performance. They provide an additional layer of protection, making them well-suited for automotive, agricultural, and industrial machinery where cleanliness is essential.

7. Cartridge Type Tapered Roller Bearings

Cartridge type tapered roller bearings are housed in a bearing unit with pre-assembled components, making them easy to install and replace. These bearings are designed to reduce assembly time and improve efficiency in applications such as automotive wheel hubs, agricultural machinery, and conveyor systems. The pre-assembled design allows for quicker maintenance and reduced downtime in industrial environments.

Benefits of Tapered Roller Bearings

-

High Load Capacity – Tapered roller bearings are designed to handle both radial and axial loads, making them ideal for

heavy-duty applications.

-

Long-Lasting Durability – The precision-engineered design and high-quality materials provide exceptional durability and

resistance to wear, ensuring a long service life.

-

High-Speed Performance – These bearings are capable of operating at high speeds without compromising performance, making

them perfect for applications such as automotive and manufacturing equipment.

-

Reduced Friction – The tapered roller design reduces friction, ensuring smooth and efficient operation while increasing

energy efficiency.

-

Versatility – With seven different types of configurations, tapered roller bearings can be customized for use in a wide

range of applications, from light-duty machinery to heavy-duty industrial systems.

-

Easy Installation and Maintenance – Many types of tapered roller bearings, such as the cartridge type, are designed for

easy installation and maintenance, reducing downtime and operational costs.

Why Choose Tapered Roller Bearings?

Tapered roller bearings are one of the most reliable and versatile bearing solutions available. Their ability to handle both radial and axial loads makes them ideal for a variety of applications, including automotive, construction, industrial machinery, and heavy equipment. With seven distinct types to choose from, you can select the bearing that best fits your specific needs based on load capacity, design configuration, and environmental factors.

Whether you're working in high-speed or heavy-duty environments, tapered roller bearings provide the performance, durability, and efficiency needed to ensure the longevity and smooth operation of your equipment.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.jpg)

ulva-Logo.jpg)