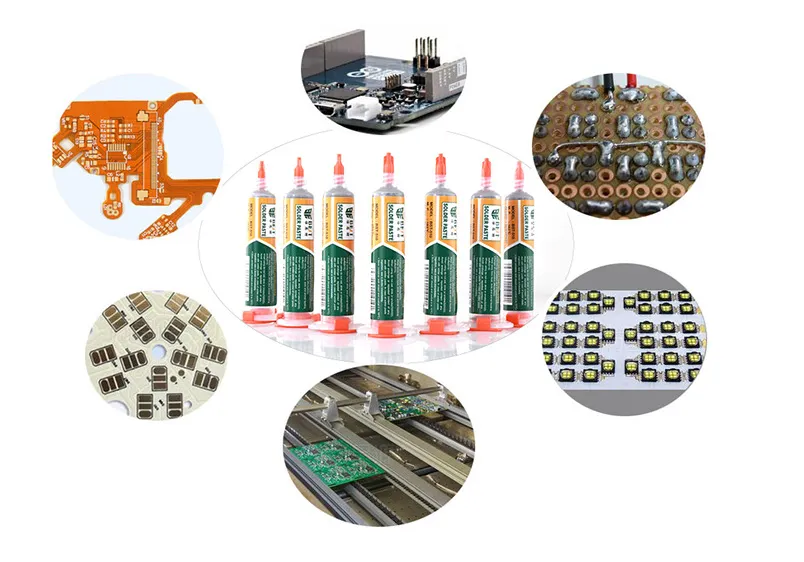

Low Temperature Solder Paste

When working with sensitive electronics, heat-sensitive components, or delicate circuit boards, low temperature solder paste is a game-changing material. Ideal for both professionals and DIY enthusiasts, this special soldering compound ensures strong, conductive bonds at much lower temperatures than conventional soldering methods, reducing the risk of thermal damage and extending the lifespan of your components.

Whether you're based in Auckland, Christchurch, or a rural workshop in the Waikato, having access to dependable, low-temp solder paste means safer, more efficient assembly and repairs—especially in environments where precision and heat control are essential.

What is Low Temperature Solder Paste?

Low temperature solder paste is a mixture of finely powdered solder alloy suspended in a flux medium. Unlike traditional solder pastes, which melt at higher temperatures (typically over 180°C), low temp solder pastes melt at significantly lower temperatures—sometimes as low as 130°C or even below. This makes them particularly suitable for:

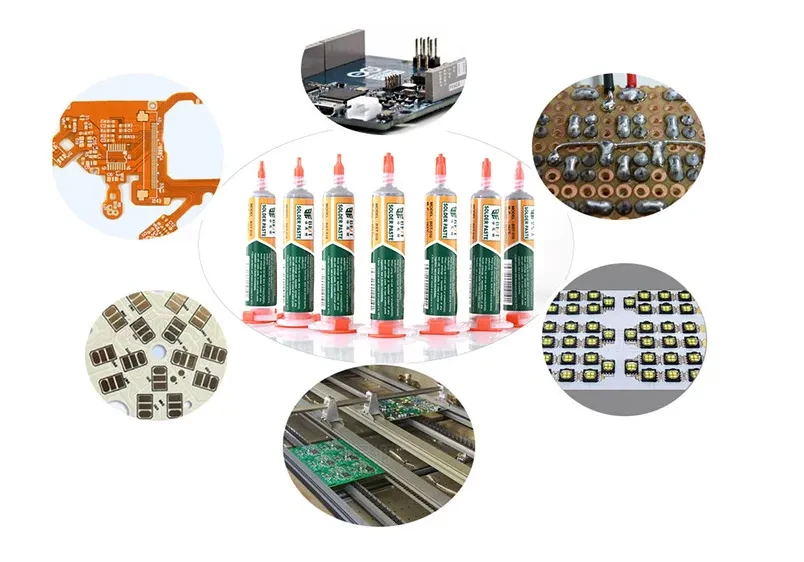

- Heat-sensitive electronic components

- LED strips and modules

- Flexible PCBs

- Multi-layer boards

- SMT (Surface Mount Technology) applications

- Rework and repair tasks

The paste usually comes in a syringe, jar, or tube and is applied directly to the pads or surfaces to be joined before heating.

Why Use Low Temperature Solder Paste in NZ?

New Zealanders pride themselves on innovation—whether it’s DIY home projects, hobby electronics, or high-tech development in fields like agri-tech, medical tech, and automation. Low temp solder paste is a valuable tool for:

-

Tech Startups: Especially those prototyping IoT devices or sensor-based gadgets where heat-sensitive plastics are involved.

- Hobbyists & Makers: Ideal for home labs where temperature control may be limited.

-

Repair Professionals: Reworking consumer electronics, laptops, or other microdevices that can’t withstand high heat.

- Education & Research: Safer for use in classrooms, uni labs, and training workshops.

- Small Manufacturers: Efficient and cost-effective for batch soldering without industrial ovens.

Benefits of Low Temperature Solder Paste

✅ Lower Risk of Heat Damage

Because the solder melts at reduced temperatures, you can avoid charring, warping, or damaging plastics, connectors, or flexible substrates.

✅ Versatile Application

Use with hot air rework stations, ovens, or even heated plates. Its consistency and spreadability make it suitable for intricate jobs.

✅ Energy Efficient

Lower operating temperatures mean reduced energy consumption—great for eco-conscious makers and cost-effective for frequent users.

✅ Time-Saving

Faster melting and quicker solidifying times can streamline production and repair processes, especially when dealing with small batch assembly.

✅ Great for Low-Temp Alloys

If your project uses low-melt materials (like some bismuth or indium alloys), this paste aligns perfectly with your thermal profile.

Use Cases in the New Zealand Context

- Repairing circuit boards in damp or cold garages where high-temp stations take too long to warm up.

- Kiwi inventors and product designers working from shared labs or co-working tech spaces.

-

Students and tutors at polytechs or unis like AUT and Massey University experimenting with electronics without the worry of

over-soldering.

- Small businesses building LED lighting systems for commercial or agricultural use.

- Rural technicians handling fragile solar controller components or off-grid electronics.

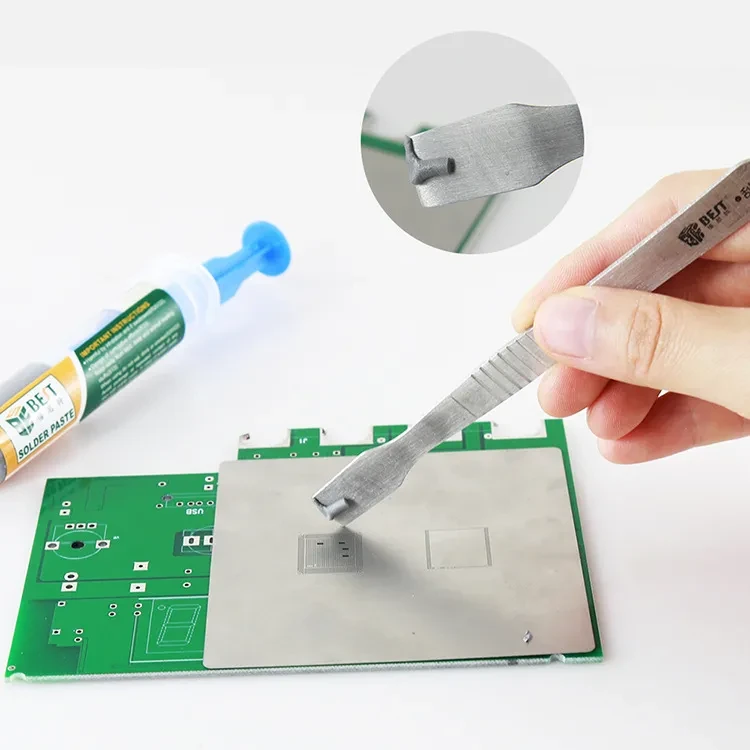

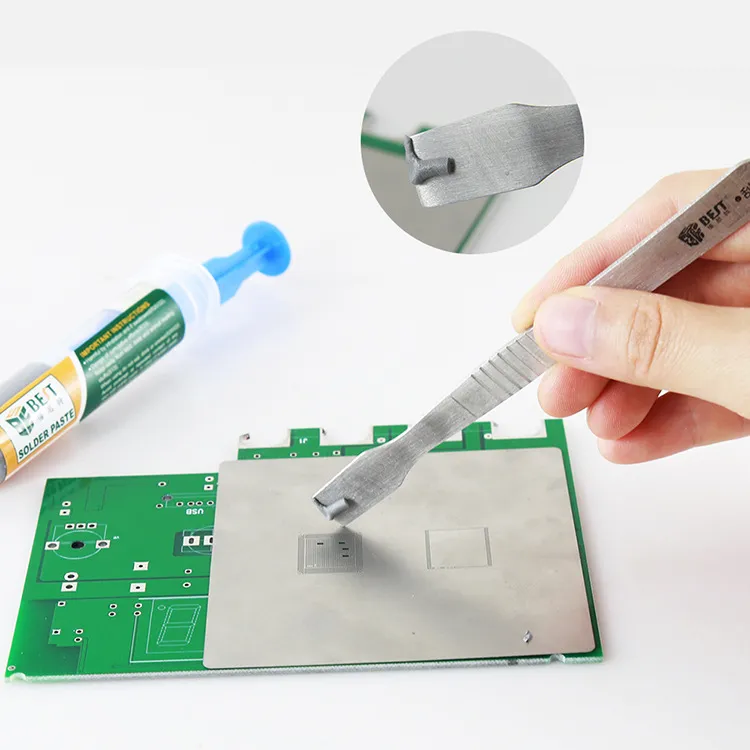

How to Use Low Temperature Solder Paste

-

Prep the Surface: Clean the PCB pads or component leads thoroughly. Remove oxidation and dirt using isopropyl alcohol.

-

Apply the Paste: Use a precision applicator, spatula, or stencil depending on your need. A thin, even layer is key.

- Align Components: Carefully place components onto the soldered areas. Use tweezers for small parts.

-

Heat Gently: Use a reflow oven, hot plate, or hot air gun to heat the paste. Monitor temperature to avoid overshooting.

- Cool Down: Allow components to cool gradually to prevent cracking or stress.

- Inspect the Joint: Look for smooth, shiny connections and double-check alignment.

Storage and Handling Tips

- Store in a cool environment, preferably refrigerated if specified.

- Avoid exposure to moisture and air—reseal tightly after use.

- Use within the recommended shelf life to ensure performance.

- Stir gently if the paste has settled or separated.

Safety Notes

Although low-temp solder paste operates at lower heat, proper ventilation and PPE are still recommended. Avoid skin contact and use in a well-ventilated workspace. If working with leaded variants, be particularly cautious and follow all local regulations on safe handling and disposal.

Choosing the Right Paste for Your Needs

Low temperature solder pastes are typically made from alloys like Sn-Bi (Tin-Bismuth) or Sn-In (Tin-Indium). Some may include silver (Ag) for enhanced conductivity and joint strength.

If you're unsure what alloy composition suits your needs, consider the following:

- Sn-Bi (Tin-Bismuth): Common, affordable, melts around 138°C.

- Sn-Bi-Ag (with Silver): Improved mechanical properties.

-

Sn-In (Tin-Indium): Ultra-low melt point (below 120°C), suitable for very delicate applications but higher cost.

Eco-Friendly and Lead-Free Options

Many modern pastes are RoHS-compliant and lead-free, making them safer for personal use and environmentally conscious projects. Perfect for NZ consumers who value green tech and safer materials.

Final Thoughts

Whether you're an electronics professional in Wellington, a hobbyist in Tauranga, or a technician in rural Otago, low temperature solder paste is a must-have tool in your workshop. Its reliability, efficiency, and heat-sensitive compatibility make it the go-to solution for precise, damage-free soldering.

No matter the scope of your project—from repairing a smartphone motherboard to prototyping the next great Kiwi tech innovation—this paste ensures clean joints, lower risks, and higher performance.

Product information:

Viscosity: 1 (Pa·S)

Granularity: 25-45 (um)

Alloy composition: tin powder

Activity: High activity

Working temperature: 250-380 (℃)

Scope of application: repair patch

Packing list:

Solder paste*1

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.webp)

.webp)

.webp)

.webp)

.jpg)

ulva-Logo.jpg)