Inventory Number Stickers

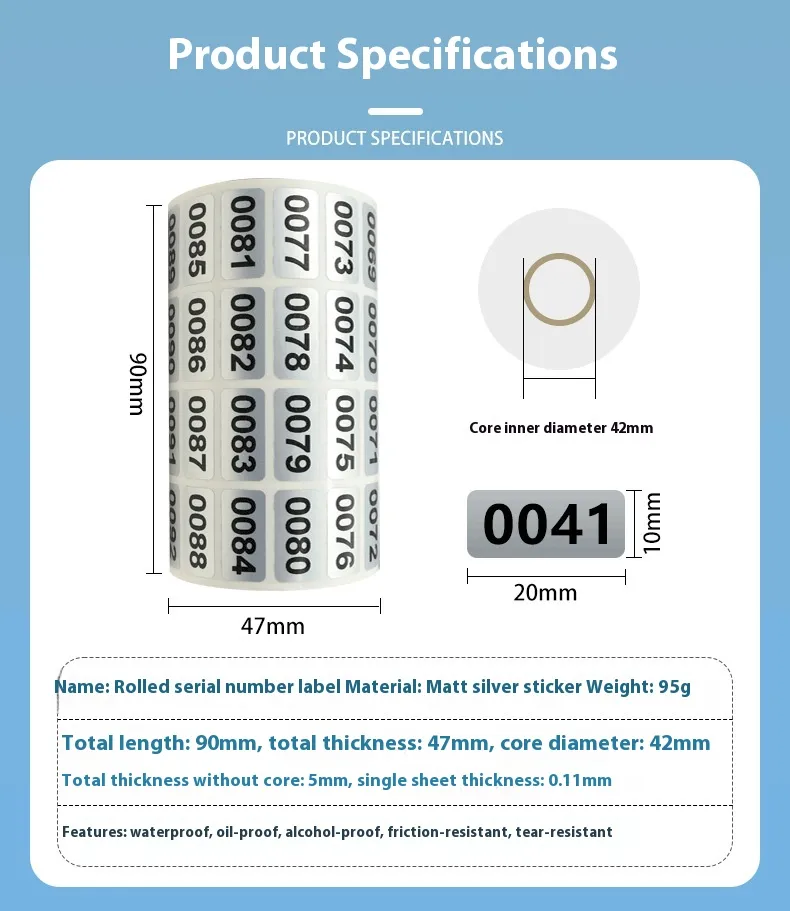

Product information:

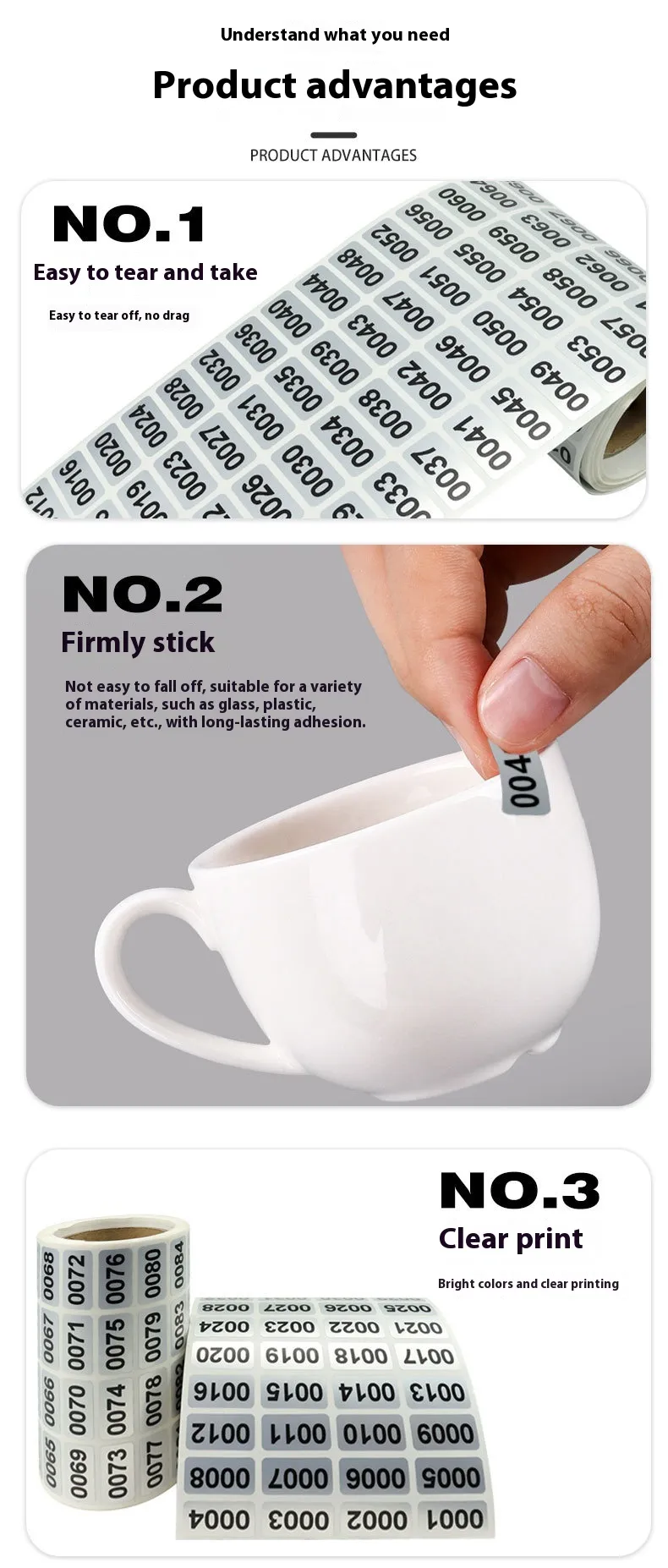

Film type: matte film

Glue type: Nail Polish

Use base paper: white base paper

Printing form: thermal printing

Material: Mat silver foil adhesive sticker

Packing list:

Digital sticker x1

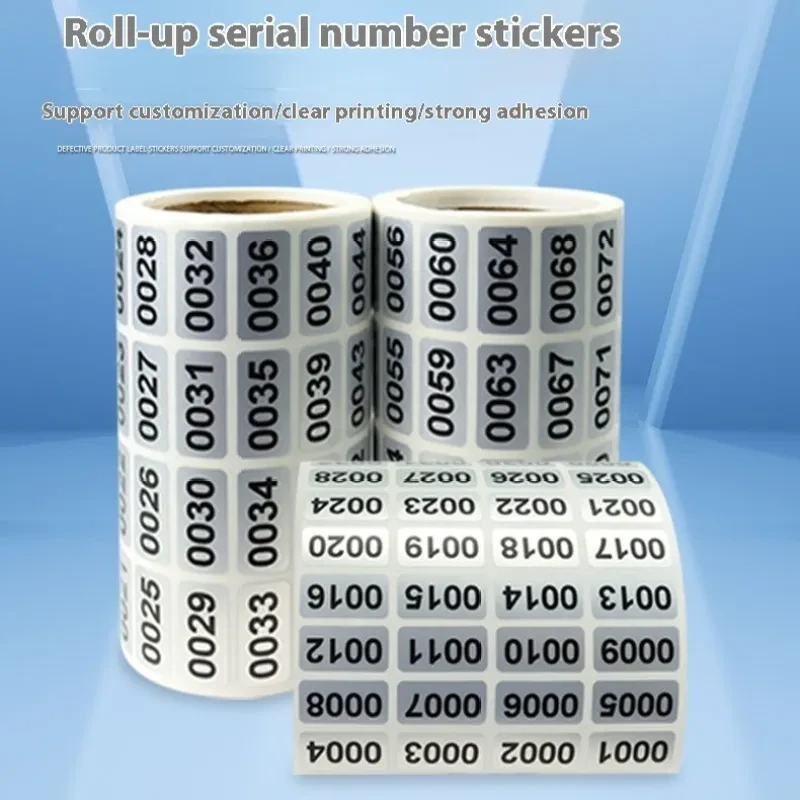

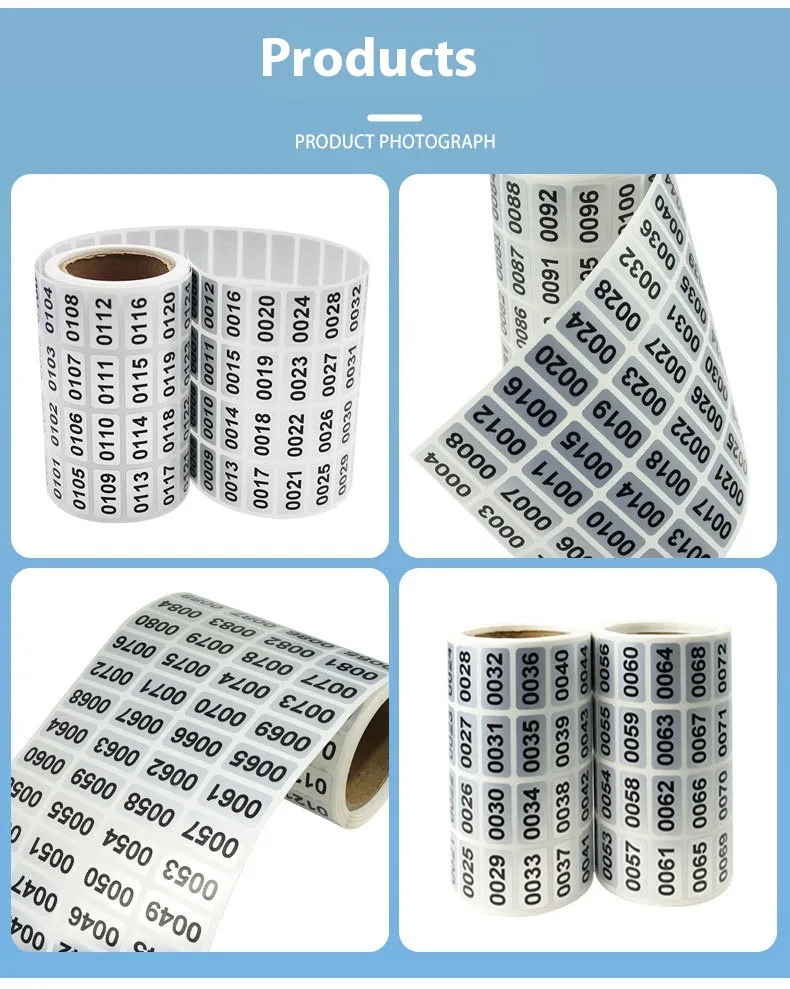

Product Image:

Inventory Number Stickers: Essential for Organized and Efficient Inventory Management

Introduction

Inventory number stickers are a simple yet crucial tool for maintaining a well-organized and efficient inventory system. Whether you are managing a retail store, warehouse, or office supplies, these stickers help ensure that your items are easily identified, tracked, and accounted for. Designed to stick firmly to various surfaces, inventory number stickers provide a visual and quick reference to help keep your products or materials organized, facilitating better stock management and reducing the risk of errors.

In this article, we’ll explore the importance of inventory number stickers, the different types available, and how they can enhance your inventory management process.

The Importance of Inventory Number Stickers

Inventory number stickers serve a variety of purposes, all contributing to better inventory control and operational efficiency. Here's why they are essential:

-

Easy Identification

Inventory number stickers are a quick and easy way to identify products or items in your inventory. By assigning a unique number to each item, you can reduce the time spent searching for products or parts, making your inventory system more streamlined.

-

Accurate Tracking

With a clear inventory number on each item, tracking becomes far more accurate. You can easily monitor stock levels, track the movement of items, and ensure that everything is accounted for during stock checks or audits. This helps prevent discrepancies between physical stock and system records.

-

Prevention of Loss and Theft

The use of inventory number stickers can help reduce loss and theft by making it easier to identify and keep track of items. When each item is uniquely numbered, it becomes harder for items to disappear without being noticed, leading to improved security.

-

Time and Cost Savings

By organizing your inventory with number stickers, you can save time when retrieving products. Employees can quickly locate the item by referencing the inventory number, speeding up the picking and packing process. This increases operational efficiency and reduces the risk of mistakes, leading to overall cost savings.

-

Ease of Auditing and Stocktaking

Conducting audits or stocktaking becomes much easier with inventory number stickers. The unique identification numbers make it simple to verify whether the right quantity of products is in stock, without having to manually count every item. The process becomes faster, more accurate, and less prone to human error.

-

Improved Customer Service

A well-organized inventory system ensures that items are easy to locate, reducing wait times for customers. With an efficient stock management process, you can respond to customer inquiries faster, provide more accurate product availability information, and ensure timely delivery of orders.

Types of Inventory Number Stickers

There are several types of inventory number stickers available, each suited for different applications and environments. Choosing the right one for your business needs is key to effective inventory management. Below are some common types:

-

Self-Adhesive Labels

Self-adhesive inventory number stickers are the most common type. These stickers have a sticky backing that allows them to be easily applied to almost any surface, such as cardboard boxes, metal, plastic, or wood. They come in a range of materials, including paper and vinyl, to suit different requirements.

-

Barcode Inventory Number Stickers

Barcode inventory number stickers are essential for businesses that utilize barcode scanning for tracking and management. These stickers feature a barcode along with the inventory number, allowing for quick and automated data entry during stock counts and product searches. They are perfect for warehouses, retail stores, and shipping departments.

-

Tamper-Evident Stickers

Tamper-evident inventory number stickers are designed to show if a product or item has been tampered with. The adhesive used in these stickers makes it difficult to remove the label without leaving a mark or damaging it. These are commonly used for high-value items or sensitive products, ensuring product security and reducing the risk of theft.

-

Color-Coded Inventory Number Stickers

Color-coded inventory number stickers are useful when you need to categorize items by type, department, or status. Different colors can represent different categories, making it easier to identify and group items. This system is particularly useful for large inventories, helping with quick visual identification.

-

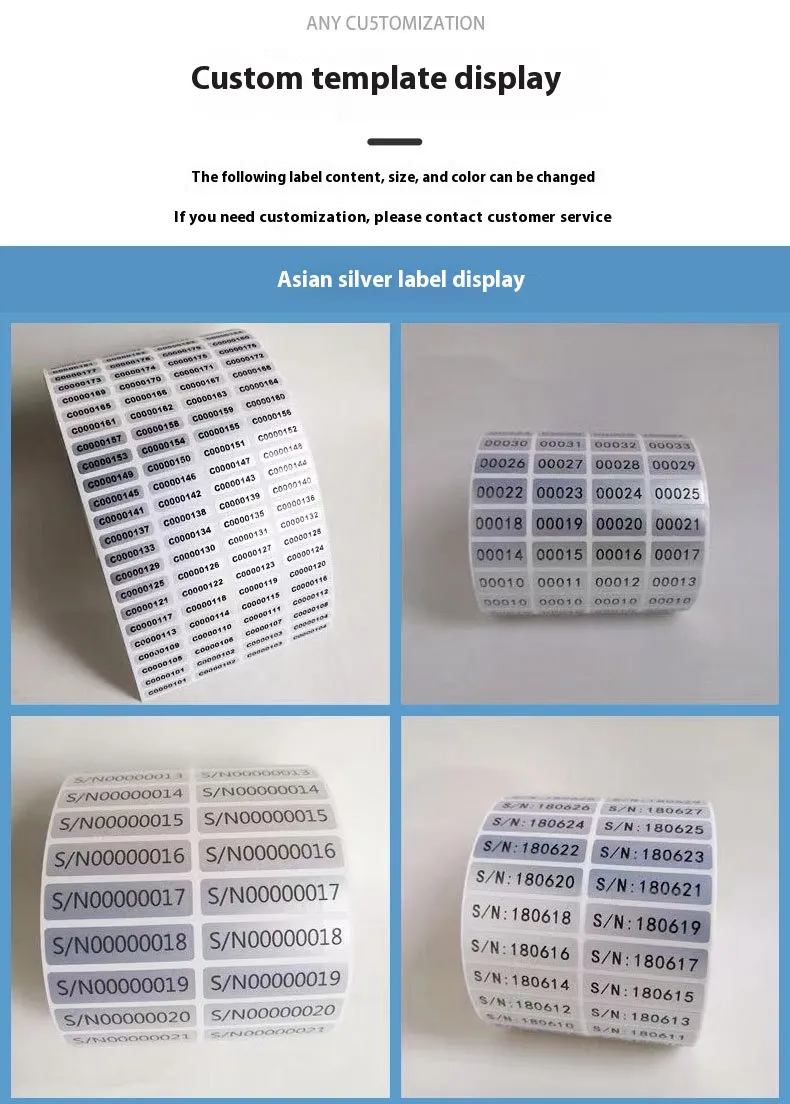

Customizable Inventory Number Stickers

Some businesses require personalized inventory stickers that include specific details such as a barcode, logo, or other identifiers. Customizable inventory number stickers allow for more flexibility and branding, enabling companies to create a sticker that aligns with their unique tracking and organizational needs.

-

Weather-Resistant Inventory Stickers

For items stored in outdoor environments or areas subject to harsh conditions, weather-resistant inventory number stickers are a must. These stickers are made from durable materials like vinyl or polyester, which can withstand moisture, sunlight, and temperature fluctuations. They remain legible and intact even in the toughest conditions.

How to Use Inventory Number Stickers Effectively

To get the most out of your inventory number stickers, here are some tips for effective usage:

-

Ensure Clear Labeling

The inventory number stickers should be clearly legible, with the number large enough to be easily visible. Avoid overcrowding the sticker with unnecessary text or information, as this can make it harder to read and process quickly.

-

Apply Stickers in a Consistent Location

Consistency is key when it comes to applying inventory number stickers. Always place the stickers in the same spot on each item or package, so they can be easily located and scanned if necessary. This practice enhances the speed of locating and managing your inventory.

-

Use a Scanning System for Barcodes

If you’re using barcode inventory number stickers, implement a barcode scanning system to make tracking even more efficient. Scanning barcodes is quicker than manual entry, reduces human error, and increases the overall efficiency of inventory management.

-

Perform Regular Audits

To maintain an accurate inventory, regularly perform audits or stock checks. During this process, use your inventory number stickers to quickly verify items, track discrepancies, and update your inventory system accordingly.

-

Store Stickers in a Dry, Cool Place

To preserve the integrity of your inventory number stickers, store them in a dry, cool place before application. This will ensure that the adhesive remains strong and that the numbers or barcodes stay clear and readable.

Conclusion

Inventory number stickers are a simple yet powerful tool that helps businesses organize, track, and manage their stock more efficiently. From enhancing identification and accessibility to reducing loss and theft, these stickers play an essential role in any inventory management system. Whether you choose self-adhesive labels, barcode stickers, or tamper-evident options, investing in quality inventory number stickers can streamline your operations, save time, and improve accuracy.

The product may be provided by a different brand of comparable quality.

The actual product may vary slightly from the image shown.

Shop amazing plants at The Node – a top destination for plant lovers

.jpg)

ulva-Logo.jpg)